thermally bonded nonwovens

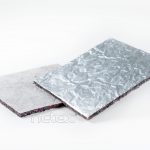

STRUTO is thermally bonded nonwoven made using a unique production technology – vertically oriented fibers.

It is made of polypropylene staple fibers and mixture of secondary raw materials. The material is produced

in various thicknesses and weights, can be combined with others in order to achieve

better required properties and can also be provided with self-adhesive layer.

Applications

STRUTO is primarily used in the automotive industry as a sound and heat insulation, damping or filling material.

Thanks to its excellent dynamic and sound-absorbing properties, STRUTO gained the reputation of high quality

among leading car manufacturers like ŠKODA AUTO a. s. and manufacturers of components

and systems for the automotive industry as Magna Exteriors & Interiors BOHEMIA s. r. o.

STRUTO

thermally bonded nonwoven

weight: 350–1500 g/m2

thickness: 6–25 mm (depends on weight)

width: 1000 mm

Alu foil + STRUTO + self adhesive layer

combination with another material

weight: 350–1500 g/m2

thickness: 6–25 mm (depends on weight)

width: 1000 mm

AMS foil + STRUTO + self adhesive layer

combination with another material

weight: 3950–5000 g/m2

thickness: 8–27 mm (depends on weight)

width: 1000 mm

Alu foil + KOBEMAT + STRUTO

combination with another material (glassfibers)

weight: 2030-3180 g/m2

thickness: 12–31 mm (depends on weight)

width: 1000 mm

AMS foil + self adhesive layer

combination with another material

weight: 3500 g/m2

thickness: 2 mm

dimensions: 1000×2000 mm

STRUTO 100% synthetics

thermally bonded nonwoven

weight: 900 g/m2

thickness: 19 mm

width: 1000 mm